01

Olenex

Deodorization columns Installation

JBC Engineering has been contracted by Olenex to install 2 off 36m tall 3.6m diameter deodorization columns. These columns have been supplied to the site in 2 sections from the equipment manufacturers in India. The bottom section of each column weighed in 50 tons and the top sections 48 tons.

JBC Engineering has worked closely with Olenex and Franz Bracht to install the columns. JBC Engineering undertook the erection, alignment and all welding of the column both inside and out to a coded standard with all required confined space works.

02

Hain Daniels

NEW AD Plant

JBC Engineering were contracted to undertake all the process pipework to provide new effluent, biogas, water, and chemical dosing pipework for this project. The entire project was achieved in a tight timescale with our on-site team navigating all the issues of integrating the old AD plant into a new AD plant.

03

Johnson Matthey

Static Ovens removal and relocation

JBC Engineering were contracted by Johnson Matthey to fully deconstruct and spilt 2 very large static ovens in their Royston facility. These ovens were split in two due to their size and transported from the UK to Poland where the ovens are currently undergoing a full overhaul to go back into service in Johnson Matthey new plant in Poland.

04

Poole Wessex Water

New Digestors Project

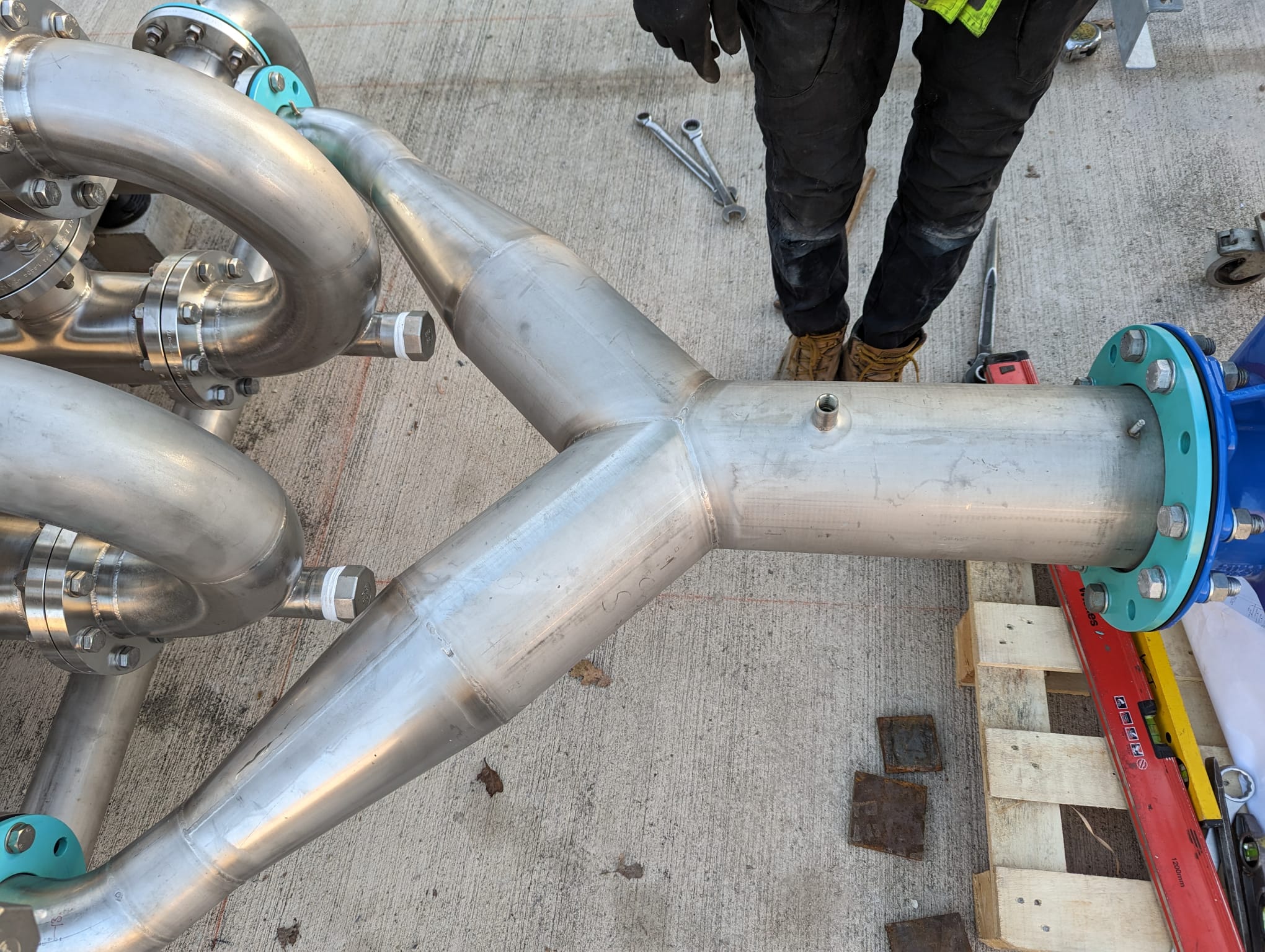

JBC Engineering were contracted by ABC stainless to install all elements of a large water treatment project in Poole. This project was to overhaul 3 off digestors on the existing site and JBC Engineering are involved in the entire project delivery with all facets of pipework fabrication and installation on site for all sludge, biogas, hot and cold water pipework, Plastic, Dual contained and steelwork installation.

JBC Engineering have been working in the water industry of both clean and dirty water plants for the last 10 years and have worked with all the major water board companies, with Anglian Water, Wessex Water, South West and East and Severn Trent water as examples

05

ADM Pura Foods

New Plate Heat exchangers

JBC Engineering was contracted by ADM Pura Foods at their edible oil site to install 3 new plate heat exchangers into their current plant room to replace their existing plate heat exchangers. This project was challenging due to the size and weight of the pipework and in a confined location and requirements for multiple inlets and outlets of the PHXs. This project was delivered on time and with thanks from the client and JBC continue to work for ADM on various projects on both its site in Purfleet and Erith on all their process pipework and installation projects.

Before

After

JBC Engineering

Before

After